Applications of LXEM Hydraulic Breakers

Concrete Structure Demolition: High-frequency impact mode for reinforced concrete buildings, bridges, and parking structures.

Foundation Removal: Precision breaking of pile caps, footings, and retaining walls without adjacent structure damage.

Roadway Rehabilitation: Pavement scarification and asphalt removal for highway and urban road maintenance.

Primary Rock Excavation: Efficient fragmentation of hard rock formations (up to 300 MPa compressive strength) in open-pit and underground mines.

Tunnel Construction: Secondary breaking in tunneling projects for oversize boulder reduction and contour shaping.

Quarry Secondary Breaking: Selective rock sizing for aggregate production, reducing blasting requirements.

Slag Removal: High-force chisels for steel mill furnace slag cleaning and ladle refractory removal.

Equipment Dismantling: Precise decommissioning of heavy machinery, boilers, and pipelines in manufacturing plants.

Shipyard Operations: Hull plating removal and bulkhead modification in ship repair and recycling.

Underwater Demolition: Watertight design for bridge pier repair, harbor infrastructure maintenance, and offshore platform decommissioning.

Urban Renewal: Low-vibration mode for restricted-access areas near hospitals, schools, and historical sites.

Frozen Ground Excavation: Enhanced impact energy for construction in Arctic regions and winter road projects.

Concrete Recycling: Breaking of demolished concrete into reusable aggregates for sustainable construction.

Scrap Metal Processing: Pre-shredding of large metal structures to facilitate recycling furnace feeding.

Trenching in Hard Soil: Efficient excavation for utility pipelines and drainage systems in compacted or rocky terrain.

Landscaping & Rockery: Precision shaping of natural stone for architectural features and garden design.

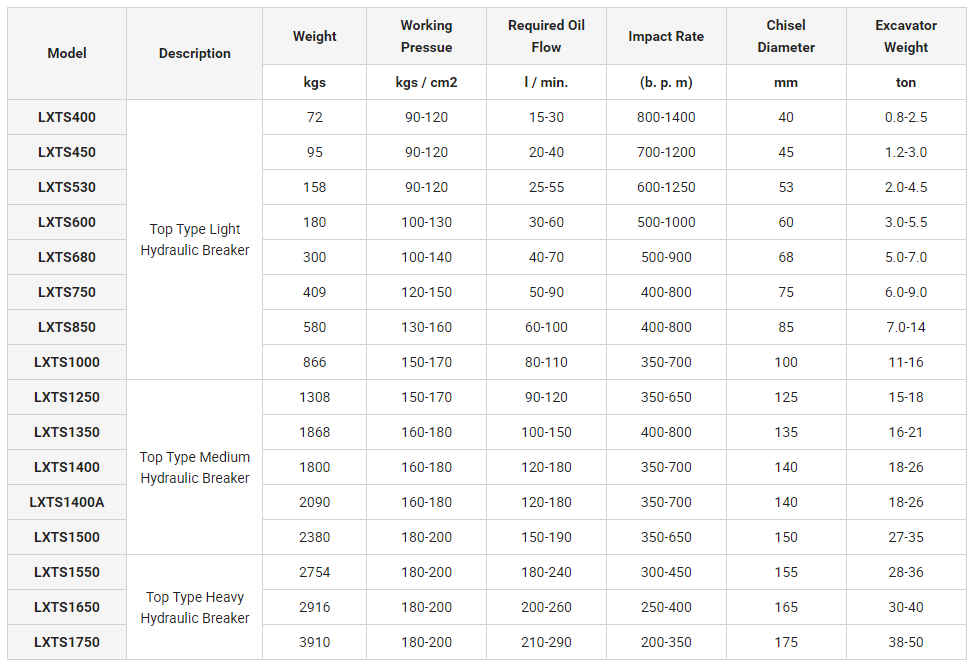

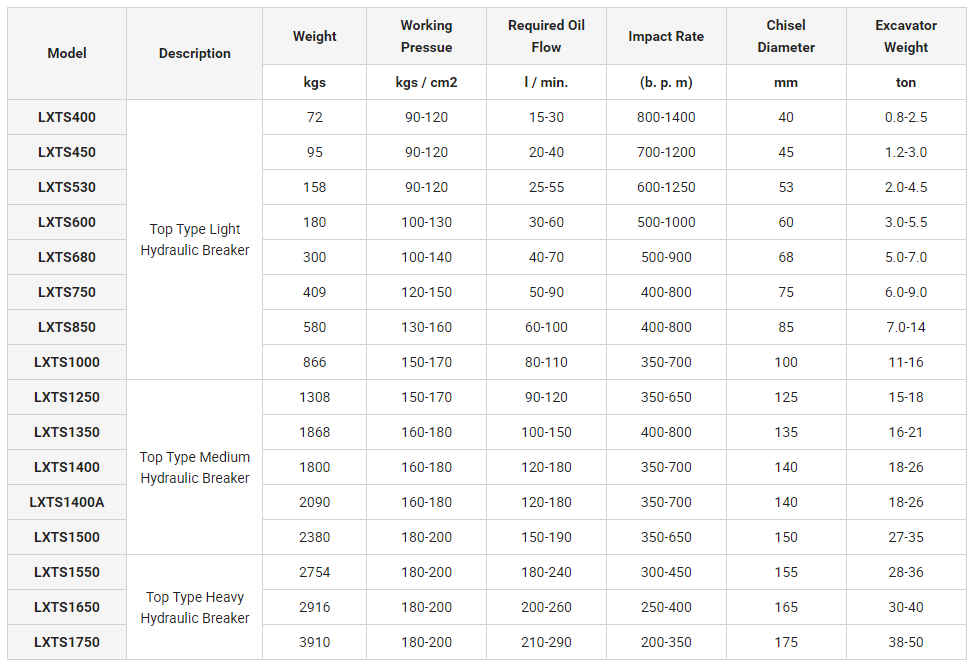

Technical Specifications

The data is for reference only, and the specific product data is subject to the actual product.

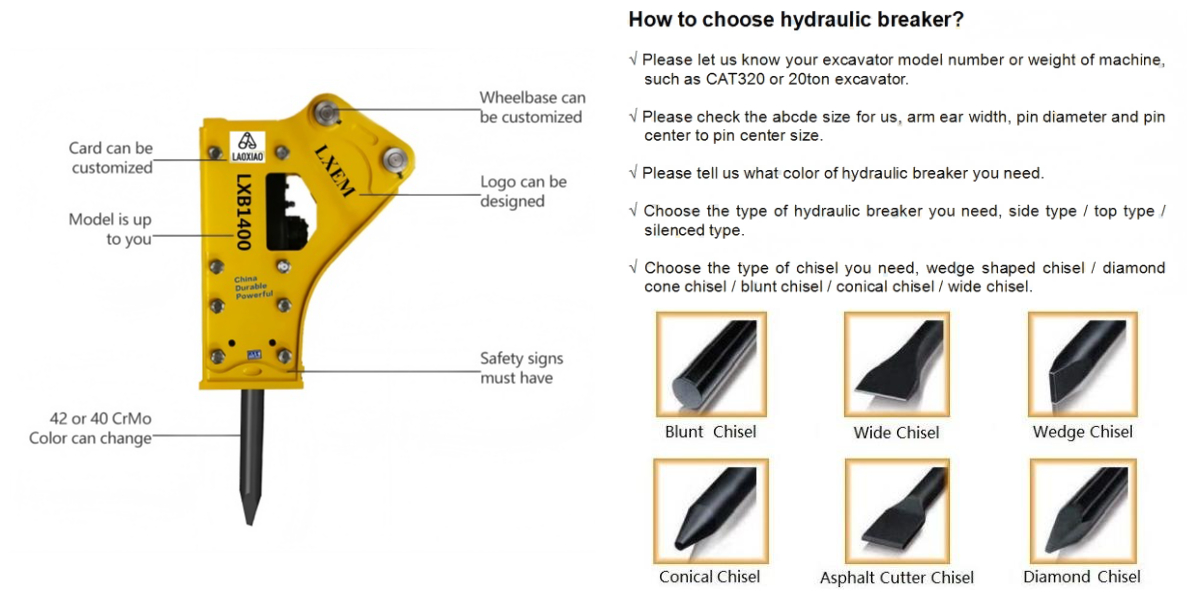

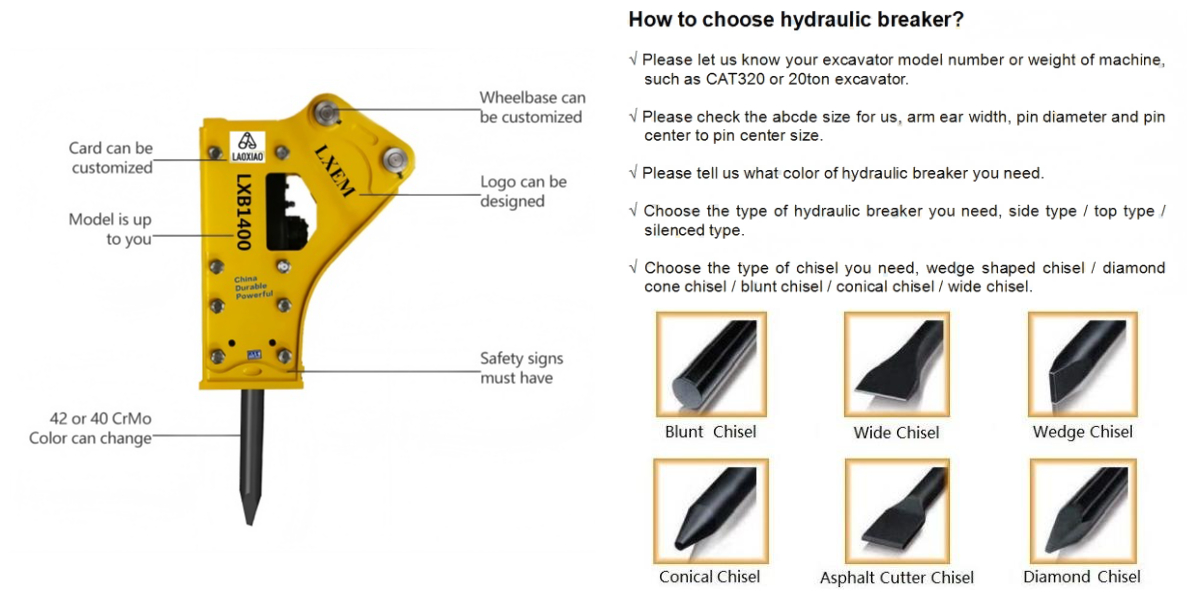

OEM Service

Our engineering team can provide tailored designs to meet specific project requirements.

Packing & Delivery